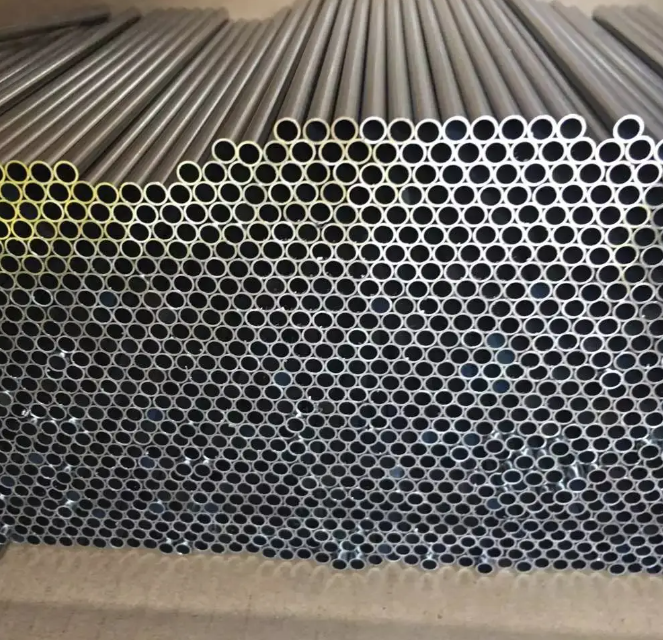

AISI ASTM A249 SS 201 304 STAINLESS

dapatkan harga terkini| Jenis bayaran: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Pengangkutan: | Ocean,Land,Express |

| Jenis bayaran: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Pengangkutan: | Ocean,Land,Express |

Model No.: 201 304 304L 316 316L 301 321 410 420 441 439 409L

Standard: JIS, AiSi, ASTM, GB, MAKAN, EN

Tempat Asal: China

Spesies: Dikimpal

Bahan: 200 Siri, 300 Siri, 400 Siri, 600 Siri

Persijilan: RoHS, ISO, IBR, BV, Sgs

Bentuk Kimpalan: Spiral Dikimpal, ERW, Efw

Bertolak Ansur: ± 1%

Perkhidmatan Pemprosesan: Membengkok, Kimpalan, Menyahtapis, Menumbuk, Keratan, Pengacuan

Nama produk: Stainless Steel Welded Round Pipe

Moq: 1 ton

Keyword: Stainless steel pipe

Technique: Hot Rolled Or Cold Rolled

Length: 1-12m or customized

Masa penghantaran: 15-30 days

Production Process: welding/ polishing

Size: customized

Surface Finish: 2B

Invoicing: by actual weight

| Unit Jualan | : | Kilogram |

| Contoh Gambar | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

|

Material

|

Stainless Steel 304/304L/316L

|

|

Shape

|

Round / Square / Rectangle

|

|

Production Standards

|

ASTM A270, ASTM A269, ASTM A249, ASTM A778, ASTM A789, DIN 11850, EN 10357, EN 10217-7 and so on.

|

|

Size

|

Outer diameter = 16 - 2000mm ;

Thickness = 0.8 - 20 mm ; Length = 6 - 18.3 meter ; Or as customer' s request. |

|

Tolerance

|

According to the Standard , +/-10% Commonly ;

|

|

Surface Treatment

|

180#, 320#, 400# Satin / Hairline, Bright Anneal, Pickle,400#, 500#, 600# or 800# Mirror finish

|

|

Process Characteristics

|

Inner Welded Seam Removed ; Online Bright Solution Anneal ; Inner Electro Polish And Mechanical Polish ;

|

|

Application

|

Petrochemical Industry ; Chemical Fertilizer Industry ; Oil Refining Industry ; Oil And Gas Industry ; Light Industry And Food Industry ; Pulp And Paper Industry ; Energy And Environmental Industries .

|

|

Test

|

Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test

|

|

Design

|

OEM / ODM / Customized

|

|

Certificate

|

ISO9001 ; ISO14001; ISO 18001; TUV ; SGS

|

|

Stainless Steel Mechanical Properties

|

||||||

|

Grade

|

Tensile Strength

|

Yide Strength

|

Elogation

|

Hardness

|

Solution

Annealing

|

|

|

kgf/mm²(N/mm²)

|

kgf/mm²(N/mm²)

|

%

|

HRB(HV)

|

ºC

|

||

|

ASTM

|

TP 304

|

≥53 (515)

|

≥21 (205)

|

≥35

|

≤90 (200)

|

1040ºC-1150ºC

Water Quenching

|

|

TP 304L

|

≥50 (485)

|

≥17 (170)

|

||||

|

TP 316

|

≥53 (515)

|

≥21 (205)

|

||||

|

TP 316L

|

≥50 (485)

|

≥17 (170)

|

||||

|

JIS

|

SUS 304

|

≥53 (520)

|

≥21 (205)

|

1010ºC-1150ºC

Water Quenching

|

||

|

SUS 304L

|

≥49 (480)

|

≥18 (175)

|

||||

|

SUS 316

|

≥53 (520)

|

≥21 (205)

|

||||

|

SUS 316L

|

≥49 (480)

|

≥18 (175)

|

||||

|

GB

|

06Cr19Ni10

|

≥53 (520)

|

≥21 (210)

|

1010ºC-1150ºC

Water Quenching

|

||

|

022Cr19Ni10

|

≥49 (480)

|

≥18 (180)

|

||||

|

06Cr17Ni12Mo2

|

≥53 (520)

|

≥21 (210)

|

||||

|

022Cr17Ni12Mo2

|

≥59 (480)

|

≥18 (180)

|

||||

|

EN

|

1.4301

|

(500-700)

|

≥20 (195)

|

≥40

|

1000ºC-1100ºC

Water Quenching

|

|

|

1.4307

|

(470-670)

|

≥18 (180)

|

||||

|

1.4401

|

(510-710)

|

≥21 (205)

|

1020ºC-1120ºC

Water Quenching

|

|||

|

1.4404

|

(490-690)

|

≥19 (195)

|

||||

|

Austenitic Stainless Steel

|

201, 301, 304, 305, 310, 314, 316, 321, 347, 370, etc

|

|||

|

Martensitic Stainless Steel

|

410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc

|

|||

|

Duplex Stainless Steel

|

S31803, S32101, S32205, S32304, S32750, etc

|

|||

|

Ferritic Stainless Steel

|

429, 430, 433, 434, 435, 436, 439, etc

|

|||

|

chemical component ( %)

|

|||||||

|

Grade ASTM

|

C

|

Si

|

Mn

|

S

|

P

|

Cr

|

Ni

|

|

201

|

≤0.15

|

≤0.75

|

5.50-7.50

|

≤0.030

|

≤0.060

|

16.00-18.00

|

3.50-5.50

|

|

304

|

≤0.07

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

17.00-19.00

|

8.00-11.00

|

|

304L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

18.00-20.00

|

8.00-12.00

|

|

309S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

22.00-24.00

|

12.00-15.00

|

|

310S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

24.00-26.00

|

19.00-22.00

|

|

316

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.045

|

16.00-18.00

|

10.00-14.00

|

|

316L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

16.00-18.00

|

12.00-15.00

|

Proses pengeluaran paip keluli tahan karat: Penyediaan keluli bulat - Pemanasan - Piercing Hot Rolling - Pemotongan Kepala - Pickling - Pengisaran - Pelinciran - Pemprosesan Rolling Dingin - Degreasing - Rawatan Haba Larutan - Lurus - Pemotongan Pipa - Pemeriksaan Produk Siap - Pickling.

Ia digunakan secara meluas dalam saluran paip transmisi perindustrian dan bahagian struktur mekanikal seperti petroleum, industri kimia,

Rawatan perubatan, makanan, industri ringan, jentera dan instrumen.

Soalan Lazim

S: Apakah kelebihan anda?A: Sudah tentu, semua produk kami diuji dengan ketat untuk kualiti sebelum pembungkusan, dan produk yang tidak layak akan dimusnahkan.

Produk lain: 304 batang bulat keluli tahan karat, bar bulat keluli tahan karat ASTM, paip keluli lancar keluli karbon, paip keluli karbon, paip keluli keluli keluli karbon, tembaga, dx51 roll galvanized, gegelung tergalvani, paip tergalvani

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.